BAT Vietnam - Energy efficiency at BAT factories in Vietnam

Over the past six years, multiple initiatives have been undertaken within BAT’s factories in Vietnam to reduce environmental pollution, promoting a shift towards a circular economy. Among these, Energy efficiency programs are one of the highlights.

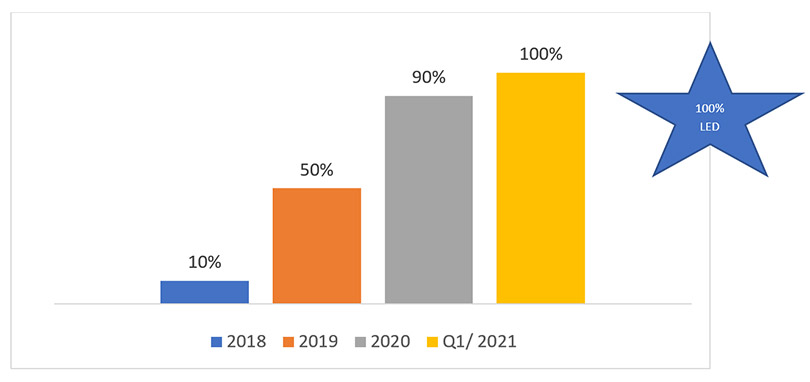

As an attempt to minimize environmental impact, BAT-Vinataba JV in Dong Nai and VINA-BAT JV in Binh Chanh District, HCMC have entirely switched from traditional light bulbs to LED lamps. As a result, the factories have saved approximately 40% of power consumption. In less than three years of conversions, the two factories managed to replace conventional light bulbs with all LED lamps by early 2021.

Lighting system at BAT-Vinataba joint venture factory in Bien Hoa, Dong Nai province has been converted 100% to LED lights.

The chart shows the process of converting 100% of lighting systems to LED of 2 factories from 2018 to early 2021.

The use of LED lamps is regarded as an efficient way to save energy, reducing the average annual energy usage by 12%, equivalent to 302 tons of CO2 emission (2018).

Another significant energy efficiency program of BAT in Vietnam is the modal shift towards biomass steam boiler at BAT-Vinataba JV in Dong Nai, thereby increasing renewable energy consumption of BAT in Vietnam to 26% in Q1, 2021, compared to 13% as planned.